However, U channels are much deeper and typically have a rounded bottom rather than a squared flat one. Sometimes a U channel will even have walls that are two different lengths so that the channel can be custom fitted to a particular area. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

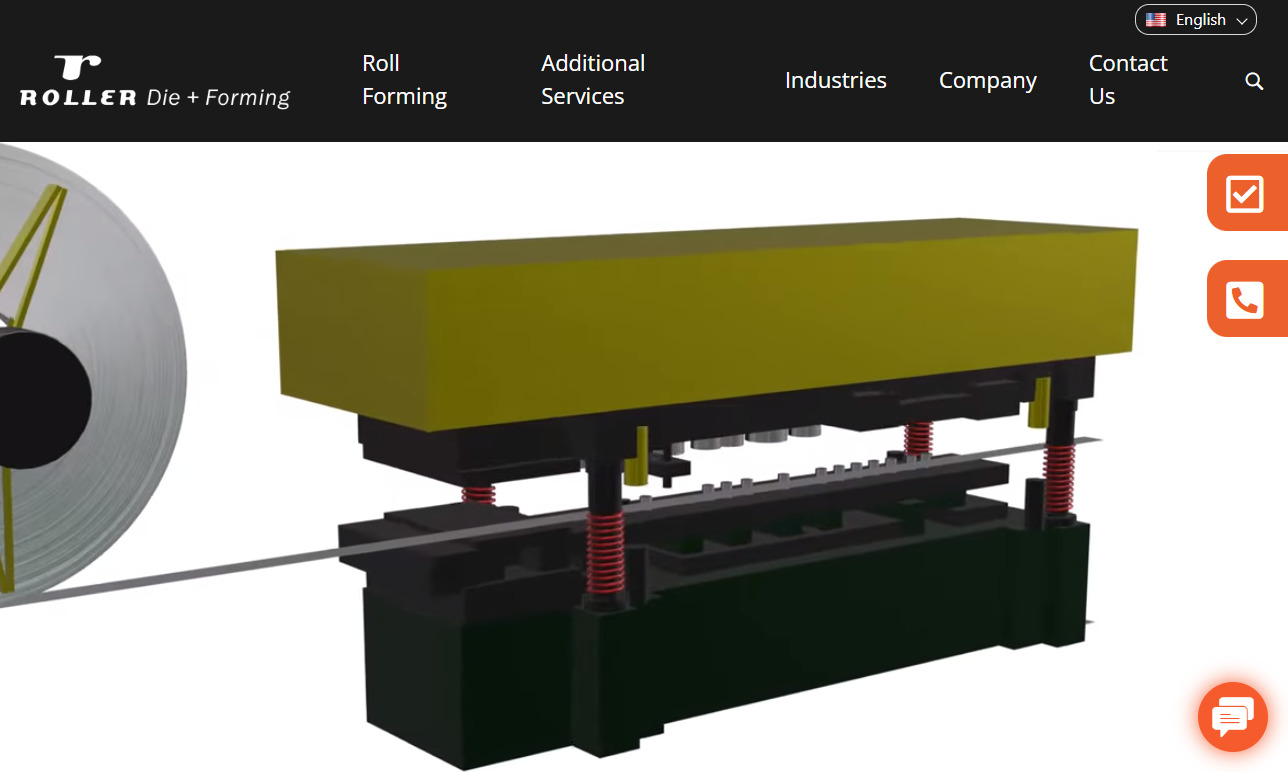

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc. They provide in-house tool room for quality metal moldings and the employees have been trained in every aspect of the roll forming process, representing over 200 years of experience.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture. Our 40,000-square-foot facility enables us to perform a variety of additional processes such as custom packaging, welding, and riveting. For more information on what we can do for you, call or visit our ...

At MMC Roll Form, we specialize in delivering precision-engineered roll formed parts tailored to meet the unique requirements of every project. With over five decades of experience, we’ve built a reputation as trusted partners in the roll forming industry by combining technical expertise with a commitment to personalized service.

More U Channel Companies

U channels can be made from a variety of plastic and metal materials, and they are a general purpose utility molding that can be used for many industries and applications.

One very common application for U channels is to use them for trim around glass in showers. A U channel can be made to fit around the edge of glass panels and add a nice finishing touch while creating a curved edge. Many contractors prefer to install aluminum U channels with a protective coating so that they do not corrode over time due to moisture exposure.

U channels are also used as railings, conduits, components in boat accessories and repair pieces for window frames. When a U channel is designed to be affixed to something, holes are drilled in the flanges or in the bottom to allow for screws or blots to pass through.

There are several roll forming methods for manufacturing U channels, but one that is becoming increasingly popular is cold roll forming. In this process, an undeformed piece is gradually bent into a U shape. This method is particularly efficient when employed on high strength sheet metal. Cold roll forming requires a specialized machine that slowly pushes the metal into the form of a U channel without having to spend time heating it.

The slow, uniform force exerted on the metal causes it to conform to the new shape without suddenly cracking. As mentioned above, U channels have many applications in residential construction, but they can also be found in industries like commercial construction, warehouse operations, and aerospace. Although they vary greatly in size, thickness and material, the concept and manufacturing process for all U channels remains very similar.

Cold Headed Parts

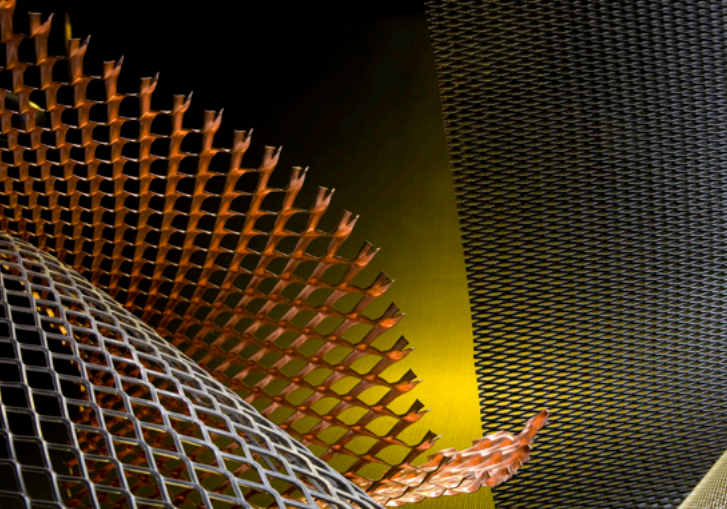

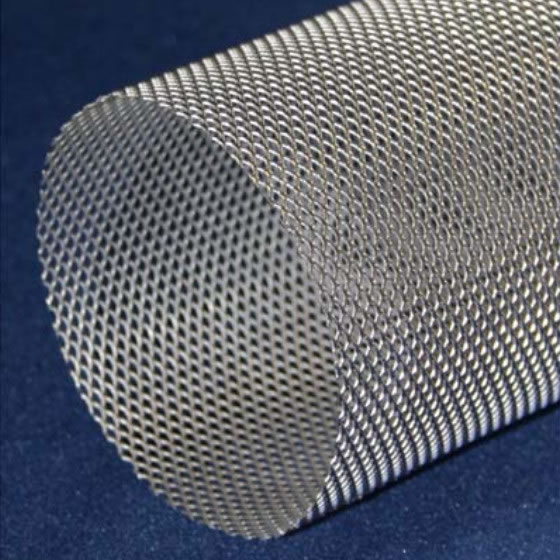

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services