Roll formers are machines that perform roll forming procedures of metals. Roll formers can also be defined as the companies that perform roll forming procedures. A long strip of metal, typically in a coil shape, is the first step in this distinctive metal-forming procedure. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

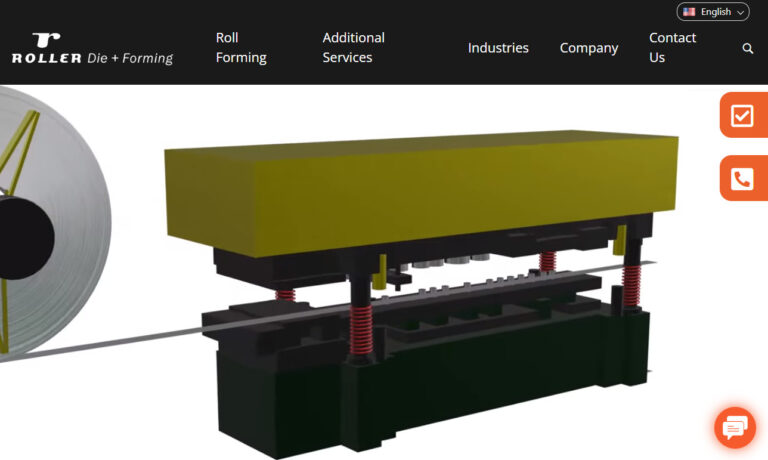

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc. They provide in-house tool room for quality metal moldings and the employees have been trained in every aspect of the roll forming process, representing over 200 years of experience.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture. Our 40,000-square-foot facility enables us to perform a variety of additional processes such as custom packaging, welding, and riveting. For more information on what we can do for you, call or visit our ...

At MMC Roll Form, we specialize in delivering precision-engineered roll formed parts tailored to meet the unique requirements of every project. With over five decades of experience, we’ve built a reputation as trusted partners in the roll forming industry by combining technical expertise with a commitment to personalized service.

More Roll Former Companies

What are Roll Formers?

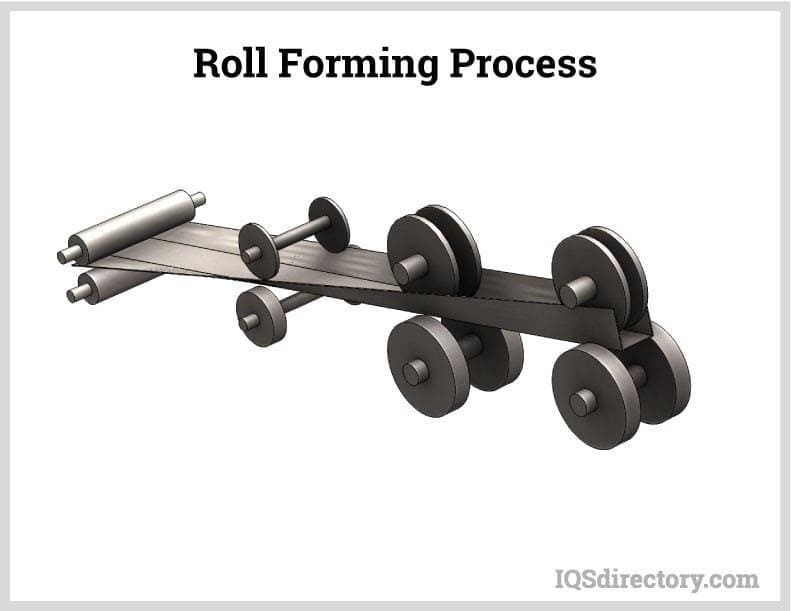

Roll formers, also known as roll forming machines or roll forming equipment, are advanced industrial machines used to shape metal sheets or strips into precise, consistent cross-sectional profiles. Through a continuous bending operation, these machines guide material—typically steel, aluminum, copper, or other metals—through a series of carefully calibrated rollers (or roll dies). Each set of rollers incrementally bends or forms the metal, gradually achieving the desired shape, such as channels, angles, or complex custom profiles. The result is a high-quality, uniform product ideal for applications in construction, automotive manufacturing, aerospace, appliance production, and countless other industries requiring metal components with tight tolerances and repeatability.

To produce a homogeneous shape, a roll forming machine pushes material through a number of mated tool dies. The workpiece is gradually bent throughout each phase of the process until it takes on the desired shape. The metal is turned, pulled, and pushed with each pass. The product is chopped to length by a machine; then, the roll forming manufacturer labels and packages it on a runoff table.

Rollers are expertly created with a flower pattern that shows the metal strip's successive modifications. Each roller's shape comprises the flower pattern's portions. Roll forming is simulated using CAD or CAM renderings so that any mistakes or faults can be fixed before manufacturing. Engineers can choose calibrations and profiles for folding or bending angles using software tools to generate new geometries by clicking their mouse.

Why Choose Roll Forming? Key Advantages

Are you comparing roll forming to other metal forming processes, such as stamping, extrusion, or press braking? Here are some compelling reasons why roll forming is often the preferred solution for manufacturing long, complex metal profiles:

- Versatility: Roll formers can create a wide variety of shapes, from simple angles and channels to intricate, custom-designed profiles for unique applications.

- Material Efficiency: Continuous processing minimizes scrap and allows for precise material usage, reducing waste and lowering overall production costs.

- Consistency and Repeatability: Automated, computer-controlled roll forming equipment delivers high-volume production with exceptional accuracy, ensuring each part matches specifications.

- High-Speed Production: Roll forming lines can operate at speeds of up to several hundred feet per minute, making them ideal for large-scale production runs.

- Superior Surface Finish: Minimal contact and gradual forming reduce the risk of scratches, cracks, or surface defects, producing visually appealing, functional parts.

- Complexity Without Sacrificing Strength: Unlike some methods, roll forming enables the creation of complex profiles while preserving the mechanical properties and strength of the base metal.

Want to learn more about how roll formers can improve your manufacturing process? Explore common applications and use cases below.

Roll Forming Process

The roll forming process is a sophisticated technique that enables the efficient, continuous production of long metal components with uniform cross-sections. Unlike traditional stamping, where the complete metal part forms in a single step, roll forming gradually shapes the material through successive stages, minimizing stress and reducing the risk of material fractures or splitting. This incremental approach allows for the creation of more complex, intricate profiles and geometries that would be impossible with conventional stamping or press forming.

In traditional stamping, the complete portion is created at once. When the forces from forming surpass what the metal can withstand before splitting, the component shape is limited, especially how complicated it can be. Only a little area of a roll-formed part is ever bent since, even here, only a small amount of forming strain is applied to the part during each station. As a result, properly designed roll forming processes can produce more complicated shapes.

A coil or several lengthy strips are passed through a roll forming line during the forming process, transforming the flat sheet into a contoured cross-sectional profile. The distinctive feature of this method is the employment of succeeding forming stations, each of which moves the metal in the direction of the desired shape.

A computer designs the track and determines the best location and form for the rollers based on the desired profile. More rollers are used as the desired form becomes more sophisticated. The roll forming line can bend metal, form it into tubes, build metal structures that resemble mazes, and punch holes in the metal.

Precision-contoured metal rollers shape the incoming sheet metal. They frequently double as rollers with motorized drives that draw the strip through the roll forming machine. The geometries of these rollers can be as straightforward as the cylindrical rollers used to push bags through airport scanners, or they can be much more complex. After the last station of forming, the strip is sheared to the desired length for the finished product.

Step-by-Step: How Does Roll Forming Work?

- Material Uncoiling: Large coils or metal strips are loaded onto an uncoiler, feeding raw material into the line.

- Feeding and Pre-Cutting (Optional): In some setups, material is pre-cut to length before forming; others use post-cutting.

- Successive Forming: The metal passes through a series of roll stands, each set incrementally bending the metal closer to its final shape.

- Punching/Notching (Optional): Integrated stations can punch holes, slots, or features into the profile as needed.

- Cut-Off: Once the desired length is reached, the formed profile is cut using a flying cut-off saw or press.

- Packaging and Labeling: Finished profiles are collected, labeled, and prepared for shipment or further assembly.

What Materials Can Be Roll Formed?

Roll forming is compatible with a wide range of ferrous and non-ferrous metals, including:

- Carbon steel (mild steel, high-strength low alloy, galvanized)

- Stainless steel

- Aluminum (including pre-painted and anodized grades)

- Copper, brass, and bronze

- Titanium and specialty alloys

Wondering if your material can be roll formed? Contact a roll forming expert for a material compatibility assessment.

Typical Applications and Use Cases

Roll formers are indispensable in a variety of industries and manufacturing settings. Some of the most common applications include:

- Construction: Metal studs, tracks, purlins, roofing and siding panels, gutters, door frames, and window components

- Automotive: Bumpers, frame rails, seat tracks, reinforcement beams, roof drip rails

- Aerospace: Lightweight structural supports, airframe components, seat tracks

- Appliances: Refrigerator frames, shelving supports, decorative trim, brackets

- Storage: Racking systems, shelving, lockers, and enclosures

- Energy: Solar panel frames, wind turbine supports, cable management systems

- Transportation Infrastructure: Guardrails, sign posts, bridge components

Searching for a roll former for a specific application? Use our RFQ form to request custom solutions from leading roll former manufacturers.

Types of Roll Formers

The different types of roll formers include:

Wrap Roll Forming

In wrap roll forming, roll forming machines create rated L-shaped edges or flanges on sheets of metal. Wrappers resemble large dining tables with a set of rollers running the table's length. They can produce both basic and complex flanges at speeds of fifty feet (15 m) per minute. This method is especially valuable for producing edge profiles on sheet metal used in construction, HVAC ducting, and appliance manufacturing where edge quality and dimensional accuracy are paramount.

Beam Roll Forming

Box beams for construction are made using beam roll forming. The plans result in beam profiles with flutes for floor framing and decking. High tensile strength steel is used to make beams, including single thickness webbing and double thickness flanges for added strength. Beam roll formers are frequently used in the production of structural steel components, highway guardrails, and architectural framing systems.

Stud and Track Roll Forming

Stud and track roll forming machines make assembly frames for sturdy, lightweight partitions that can be up to 32 feet (9.75 m) long with a variety of thicknesses. These machines are essential in the rapid production of components for drywall partitions, ceiling grids, and load-bearing wall systems in both residential and commercial construction.

Angle Roll Forming

The most fundamental of the roll formed profiles, equilateral or uneven perpendicular angles, are manufactured by angle roll forming machines using high tensile strength steel. Roll formed angles are mostly used for framing, although they can also be used for rails, posts, supports, and brackets. Angle roll forming is a cost-effective solution for producing long, straight angles used in industrial racking, storage solutions, and reinforcing structures.

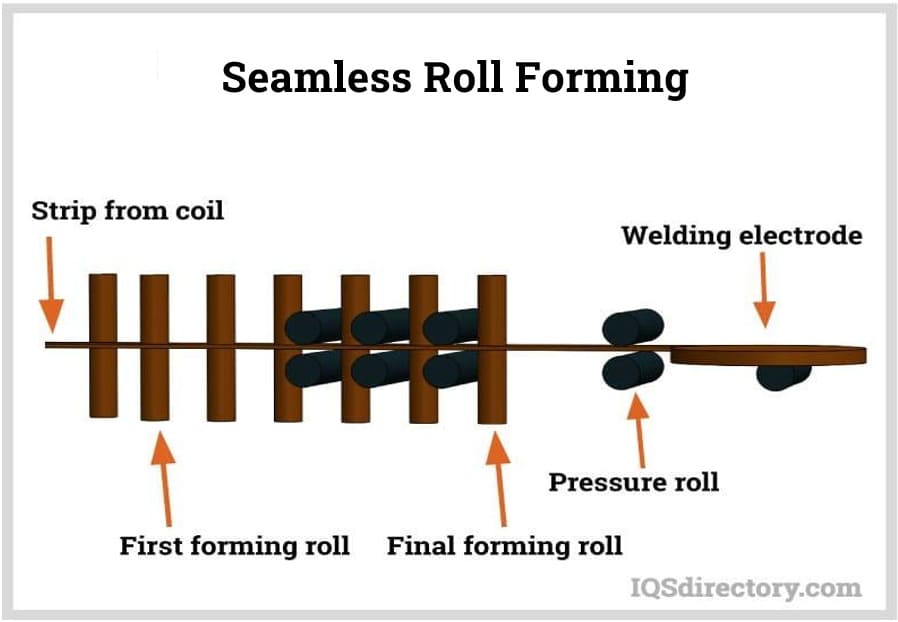

Seamless Roll Forming

The production of rectangular, square, oblong, and circular tubing is the main application for seamless roll forming. A rolled tube is joined together using the TIG process at the conclusion of the roll forming procedure, as shown in the diagram. Tubing is manufactured from various ferrous and non-ferrous metals, just like many roll-formed items. Seamless roll formed tubing finds applications in automotive frames, HVAC conduits, furniture, and architectural fixtures where a continuous, smooth finish and high strength are required.

Custom Roll Formers

For unique applications, custom roll former machines can be engineered to produce non-standard shapes, complex profiles, or to integrate additional operations such as in-line welding, embossing, or fastening. When off-the-shelf solutions can't meet your specifications, custom roll forming equipment ensures you achieve the exact dimensions, tolerances, and features needed for your project. Request information about custom roll former design and integration.

Comparing Roll Former Machine Types: Which Is Right for You?

- Manual Roll Formers: Ideal for low-volume or prototyping applications requiring flexibility and lower cost.

- Semi-Automatic Roll Formers: Strike a balance between throughput and operator control, suitable for medium-scale production.

- Fully Automatic Roll Formers: Maximize speed, consistency, and integration with CNC controls; perfect for high-volume industrial manufacturing.

Not sure which roll former fits your production goals? Submit your requirements for expert guidance and machine selection.

Benefits of Roll Forming Technology

Roll forming technology provides several advantages for manufacturers seeking high-quality, cost-effective metal components:

- Reduced Production Costs: High efficiency and low scrap rates help lower per-unit cost, especially for long production runs.

- Enhanced Product Strength: The gradual bending process retains the base material's mechanical properties, resulting in robust and durable components.

- Design Flexibility: Ability to produce unique, complex, or multi-functional profiles that are difficult or impossible with stamping or extrusion.

- Scalability: Easily adaptable to increased production volumes without significant retooling.

- Integration: In-line operations such as cutting, punching, embossing, and welding can be incorporated to streamline workflow and reduce labor costs.

- Improved Lead Times: Automated processes and high-speed lines shorten delivery schedules for large orders.

Curious about how roll forming can improve your metal fabrication process? Speak with a roll forming specialist today.

Choosing the Proper Roll Former Manufacturer

Finding the right roll former manufacturer is crucial for maximizing your return on investment and ensuring seamless integration into your manufacturing operations. Whether you're sourcing a new roll forming machine, upgrading your line, or seeking a custom solution, evaluating potential suppliers based on quality, experience, and support is paramount.

How to Evaluate Roll Former Manufacturers

- Industry Experience: Look for manufacturers with a proven track record in your sector, whether automotive, construction, or other specialized industries.

- Engineering Capabilities: Assess their ability to design custom tooling, integrate in-line operations, and offer technical support for complex profiles.

- Quality Assurance: Ensure they follow ISO or relevant industry standards for manufacturing and testing.

- After-Sales Support: Consider access to spare parts, maintenance services, and training for your operators.

- Production Capacity: Match their manufacturing scale to your volume requirements and delivery timelines.

- Customer References: Request case studies or testimonials from similar projects to gauge satisfaction and reliability.

Get the Best Value: Compare Roll Former Manufacturers

To make sure you have the most productive outcome when purchasing roll formers from a roll former manufacturer, it is important to compare at least 5 companies using our list of roll former manufacturers. Each roll former manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each roll former business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple roll former businesses with the same message.

Key Questions to Ask Before You Buy

- What types of roll former machines do you specialize in?

- Can you provide references for similar projects or industries?

- What is the average lead time for new machines or replacement parts?

- What support services do you offer (installation, training, maintenance)?

- Do you offer custom roll forming solutions to meet unique requirements?

Ready to Request a Quote?

Use our RFQ form to connect with leading roll former manufacturers. Provide your project specifications, material requirements, and desired features to receive competitive proposals. Our network of suppliers can help you source the right roll forming equipment, whether you need a standard profile machine or a fully custom, integrated roll forming line.

Frequently Asked Questions About Roll Formers

What is the difference between roll forming and stamping?

Roll forming is a continuous bending process ideal for producing long, complex metal profiles with consistent cross-sections, while stamping is a single-step process best for producing individual parts in high volumes. Roll forming is preferred when part length, profile complexity, and surface finish are critical.

What industries use roll forming machines?

Industries such as construction, automotive, aerospace, HVAC, appliance manufacturing, energy, and storage systems all rely on roll formers for custom metal profiles and components.

How do I select the right roll forming machine for my application?

Consider factors such as your required profile shape, material type and thickness, desired production speed, integration needs (such as punching or welding), and available space. Consult with experienced roll former manufacturers for application-specific recommendations.

Can roll forming machines handle pre-painted or coated materials?

Yes, modern roll forming equipment can process a wide range of materials, including pre-painted, pre-anodized, or coated metals, while preserving the integrity and appearance of the surface finish.

How much does a roll former cost?

The price of a roll forming machine varies widely based on type, complexity, speed, and customization. Manual machines may start under $20,000, while fully automated, high-capacity lines with integrated operations can exceed several hundred thousand dollars. Ask for detailed quotes including installation and after-sales service.

Contact a Roll Forming Expert

Have more questions or need a tailored solution? Reach out today to get personalized advice, explore roll forming machine options, and connect with top-rated roll former manufacturers. Let us help you find the ideal equipment for your application, from standard machines to advanced custom roll forming systems.

Ready to take the next step? Request a quote or consultation for your roll forming needs now.

Cold Headed Parts

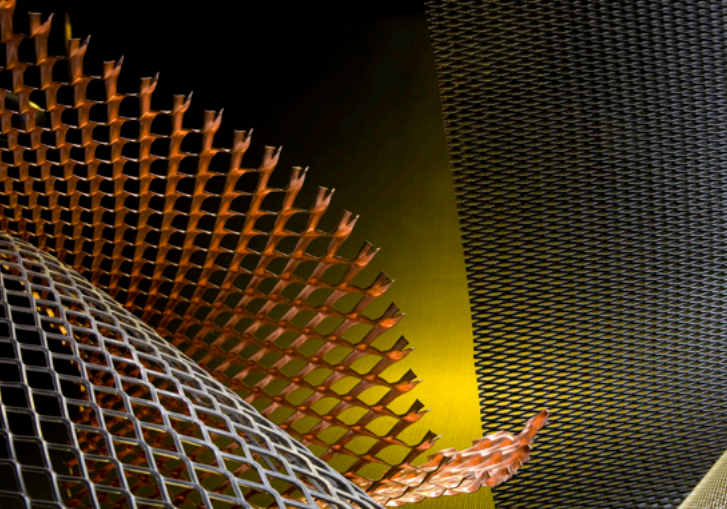

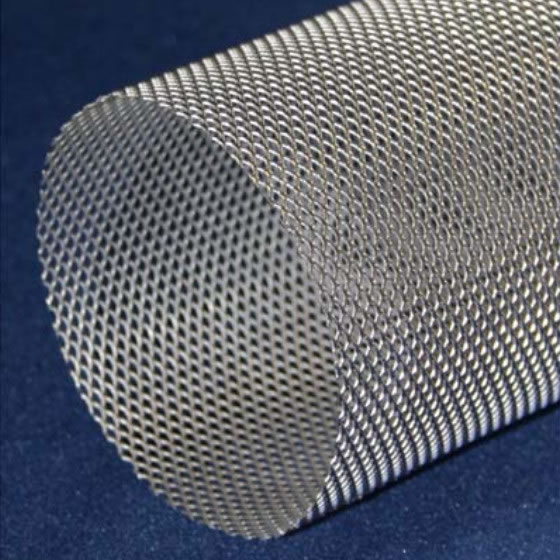

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services