Aluminum, steel, and plastic are a few of the materials used to make J-channels. The trim around windows, doors, and the border of gables is where J-channels are most frequently employed as a finishing touch. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc. They provide in-house tool room for quality metal moldings and the employees have been trained in every aspect of the roll forming process, representing over 200 years of experience.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture. Our 40,000-square-foot facility enables us to perform a variety of additional processes such as custom packaging, welding, and riveting. For more information on what we can do for you, call or visit our ...

At MMC Roll Form, we specialize in delivering precision-engineered roll formed parts tailored to meet the unique requirements of every project. With over five decades of experience, we’ve built a reputation as trusted partners in the roll forming industry by combining technical expertise with a commitment to personalized service.

More J Channel Companies

What are J Channels? (Definition, Purpose & Uses)

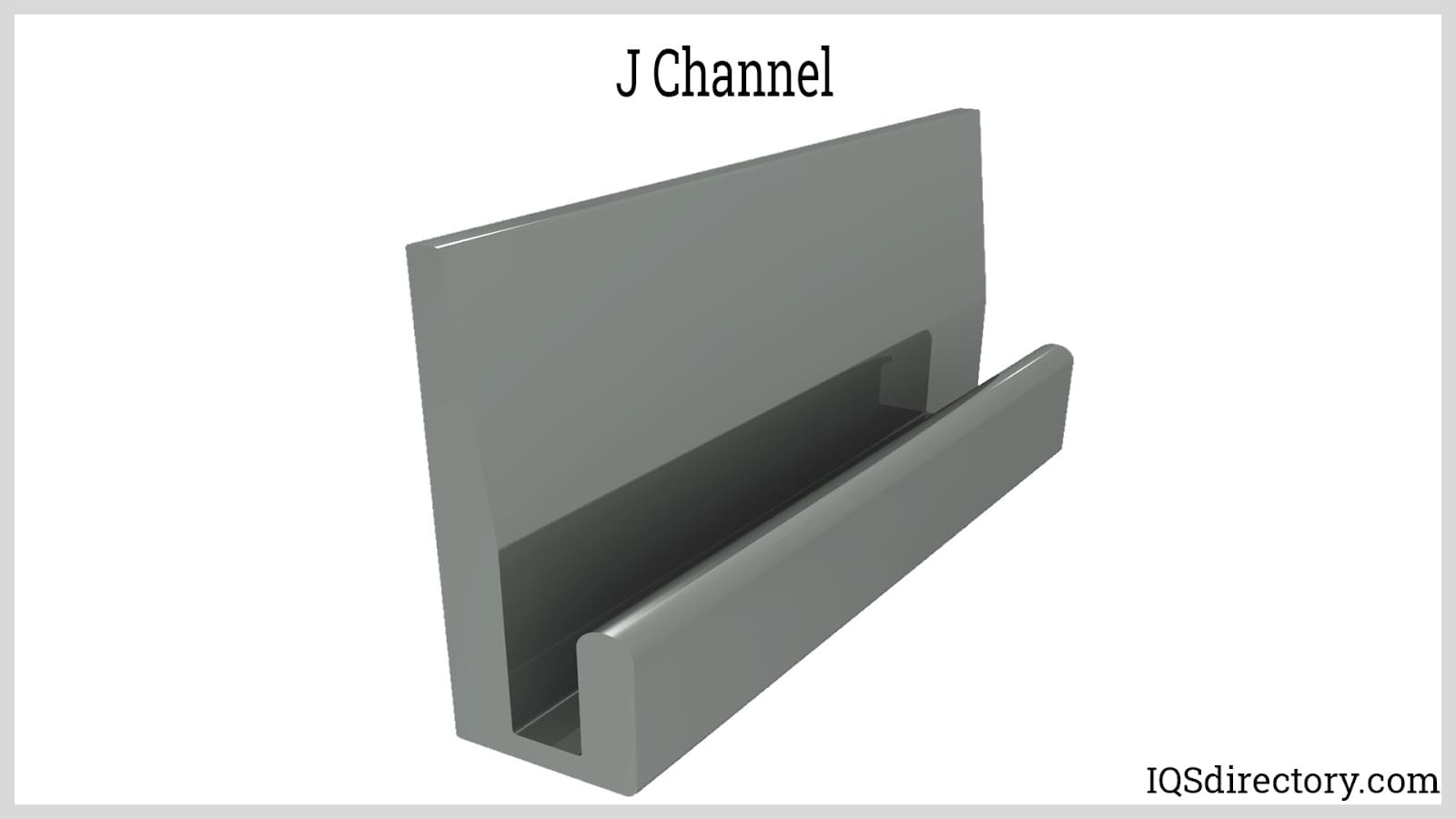

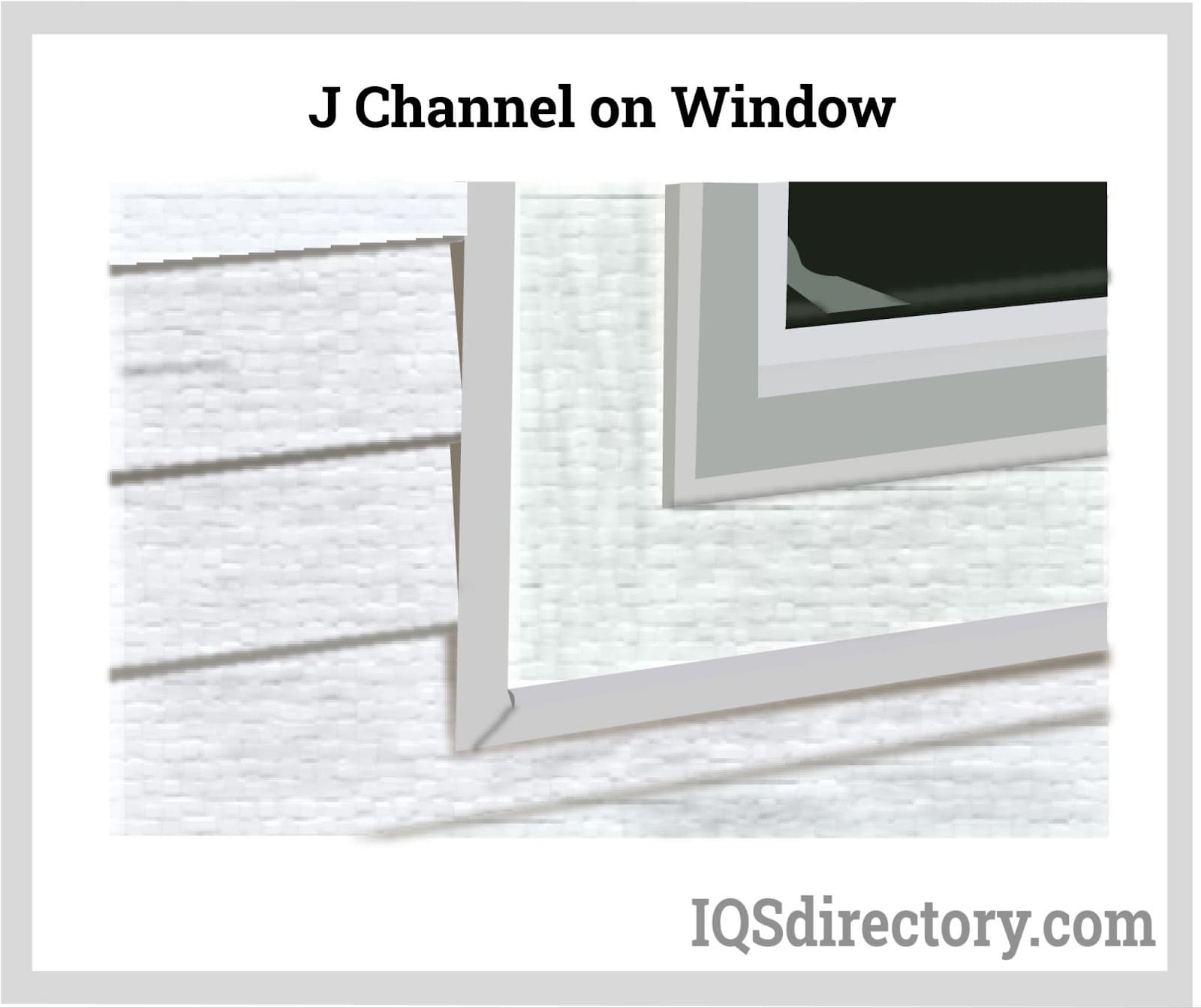

J-channels are versatile building components used primarily as trim and edge-protection solutions in construction, siding installation, and architectural finishing. Their signature hooked "J" shape on the end of the flange makes them easy to install, typically by trimming them to size and snapping them into place. The unique design—with one channel side longer than the other—creates a profile resembling the letter "J." This configuration allows J-channels to securely hold siding edges, window trims, and other building materials, providing both a finished look and enhanced weather resistance.

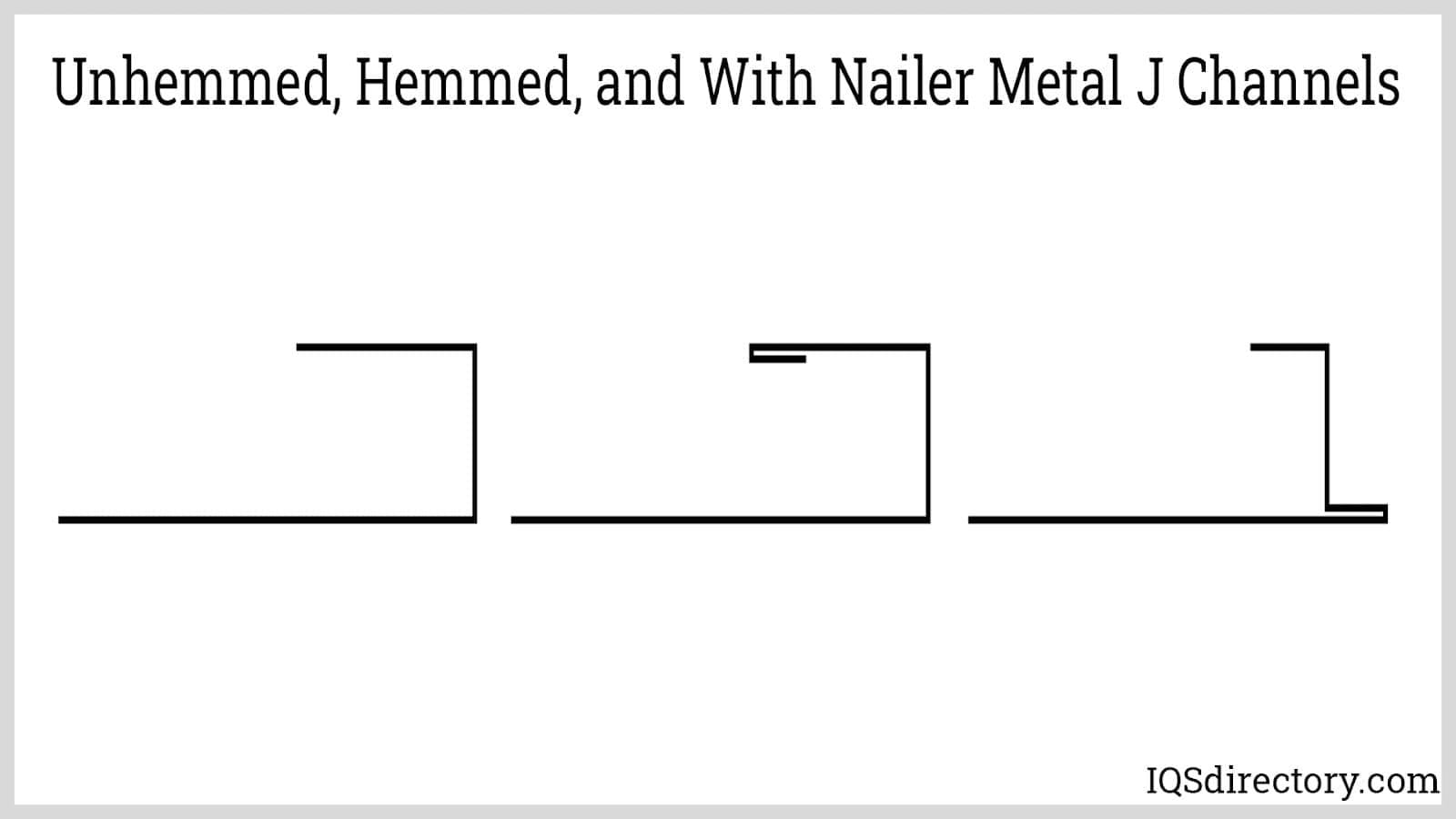

There are several types of J-channels to address diverse application requirements in residential, commercial, and industrial construction. The most popular varieties include:

- Straightforward J-channel (without hem): A basic, cost-effective trim ideal for simple edge protection.

- J-channel with hem: Features a reinforced edge for greater strength, durability, and safety—useful in high-traffic or exposed areas.

- J-channel with flat mounting piece: Designed for easy attachment with screws or nails, providing a secure fit for heavier or specialty installations.

J-channels are manufactured in various lengths, typically ranging from a few feet up to 20 feet (6 meters) or more. This wide range allows for seamless integration into different construction projects and minimizes waste during installation.

Why are J-Channels Essential in Construction and Siding?

J-channels play an integral role in modern construction, especially for vinyl siding, metal siding, and window or door trim installations. They serve multiple functions, including:

- Edge Protection: Prevents water infiltration and shields siding edges from wind, debris, and pests.

- Enhanced Aesthetics: Provides a clean, finished appearance by concealing raw siding edges and framing transitions between surfaces.

- Versatile Compatibility: Can be used with vinyl, aluminum, steel, wood siding, soffits, and various architectural panels.

- Moisture Management: Directs rainwater away from vulnerable seams, reducing the risk of leaks and rot.

- Easy Customization: Readily trimmed and shaped to fit complex corners, curves, or non-standard openings.

Because J-channels are available in a wide variety of materials and finishes, they can be matched to any exterior or interior design scheme, making them a preferred choice for builders, contractors, and home improvement professionals.

Manufacturing Process of J Channels

The manufacturing of J-channels is a streamlined process designed for efficiency, durability, and aesthetic flexibility. Many manufacturers produce all-weather J-channels for retail and wholesale distribution, catering to hardware stores, construction supply outlets, and custom builders.

Finishing Options: To blend with or accentuate existing siding, J-channels may be finished with colors, textures, or woodgrain patterns. For example, some offer a brown, grainy texture that imitates the appearance of real wood trim, providing the natural look of wood without ongoing maintenance.

Installation Benefits: J-channels are quicker and more cost-effective to install than genuine wood, and they offer superior resistance to rot or decay from moisture exposure. Beyond exterior use, J-channels are also popular as decorative trims for interior window frames, doorways, shelving, and cabinetry.

How are J-Channels Made? (Plastic vs. Metal)

The specific manufacturing process for J-channels depends largely on the material:

- Plastic J-Channels: Produced through extrusion molding, where heated plastic is shaped into a J-channel profile as it cools in a mold. The resulting lengths are then cut to size for distribution and installation.

- Metal J-Channels: Manufactured from sheet metal, which is formed into the J-shape using roll forming or press brake machinery. Hot or cold roll forming applies slow, even pressure to achieve precise, consistent profiles. This method enables high-volume production and rapid turnaround for contractors and suppliers.

Customization: Leading manufacturers may offer custom J-channel fabrication for unique construction requirements—such as unusual shapes, sizes, or finishes—to ensure a perfect fit for specialty projects.

Materials Used to Make J Channels

J-channels are available in a variety of materials, each offering unique benefits for different applications. Choosing the right material impacts longevity, aesthetics, cost, and suitability for specific environments.

- Stainless Steel J-Channels:

- Stainless steel is highly favored for roll forming metal channels due to its mechanical strength, corrosion resistance, and attractive finish. Common grades include 304 and 316, with 304 being especially popular for its versatile performance and cost-effectiveness.

- Stainless steel's alloy composition (primarily chromium and nickel) gives it exceptional resistance to oxidation, rust, and harsh environments, making it ideal for industries that demand sanitation and cleanliness—such as food processing, laboratories, and medical facilities.

- If you're seeking a long-lasting, low-maintenance J-channel for exterior or industrial applications, stainless steel is a top choice.

- Aluminum J-Channels:

- Aluminum is prized for its lightweight nature, strength-to-weight ratio, and adaptability. While not as strong as steel, it offers sufficient structural support for many projects.

- Applications include frame extensions, light poles, window and door frames, lighting fixtures, connectors, and ladder rails.

- Aluminum's natural oxide coating provides basic corrosion protection, which can be enhanced with powder coating or anodizing—ideal for outdoor or harsh environments.

- Looking for a lightweight, corrosion-resistant trim? Aluminum J-channels are often chosen for both commercial and residential siding, especially where electrical conductivity and easy handling are desired.

- PVC and Vinyl J-Channels:

- PVC (polyvinyl chloride) and vinyl J-channels are non-conductive, highly weather-resistant, and cost-effective—making them the go-to choice for vinyl siding and non-metallic trim applications.

- They are available in a wide range of colors and are easy to cut and install, making them popular in both DIY home improvement and professional construction projects.

- Interested in a maintenance-free solution for your siding? Vinyl J-channels require no painting and resist fading, cracking, and warping even in extreme climates.

- Galvanized Steel J-Channels:

- Galvanized steel J-channels are coated with zinc for enhanced corrosion resistance, making them suitable for exterior use where exposure to moisture is common.

- They offer a balance between strength, affordability, and durability—especially in commercial, agricultural, and industrial buildings.

- Need a robust, budget-friendly trim? Galvanized J-channels are a smart choice for large-scale siding or roofing projects.

Applications of J Channels

J-channels are utilized across a vast array of industries and building types, thanks to their adaptability, strength, and clean appearance. Their primary function is to secure and finish the edges of panels, but their use cases extend far beyond basic siding installation.

- Sign Hangers and Holders: J-channels act as mounting tracks for signs in retail stores, offices, and public buildings, making installation and updates quick and secure.

- Separators & Decorative Trim: Provides a finished, professional edge to wall panels, partitions, furniture, and cabinetry. Decorative J-channels enhance the visual appeal of both residential and commercial interiors.

- Photo Frames: Used as framing channels for artwork, mirrors, and glass panels.

- Wire Management & Cable Organization: Facilitates neat, protected routing of electrical wires and networking cables in data centers, offices, and manufacturing environments.

- Conductor Bar Protectors & Bus Bar Insulators: Insulates and safeguards electrical conductors in power distribution systems, switchgear, and industrial machinery.

- Window and Door Trim: J-channels are essential for creating clean, watertight transitions around window and door openings, especially in vinyl and metal siding systems.

- Soffit and Fascia Systems: Used to hold soffit panels in place and provide a finished edge along rooflines and eaves.

- Roof Edging and Flashing: Prevents water intrusion at roof-to-wall intersections and other vulnerable areas.

- Greenhouses and Agricultural Buildings: J-channels secure polycarbonate or acrylic panels in greenhouse construction, offering weather resistance and easy panel replacement.

How to Select the Right J Channel for Your Project

Choosing the best J-channel for your application involves considering several factors, ensuring optimal performance, longevity, and aesthetics. Here are key decision points to guide your selection process:

- Material Compatibility: Match the J-channel material (vinyl, aluminum, steel, stainless steel) to your siding, panel, or architectural finish for consistent appearance and durability.

- Environmental Conditions: Consider exposure to weather, moisture, chemicals, or temperature extremes. Stainless steel and galvanized steel are excellent for harsh environments, while vinyl is ideal for moderate climates.

- Load and Structural Requirements: For heavy-duty or load-bearing applications, choose steel or reinforced J-channels. For decorative or lightweight trim, aluminum or vinyl may suffice.

- Color and Finish: Select a finish that matches or complements your siding or architectural design. Many suppliers offer custom color matching and textured finishes.

- Ease of Installation: Some J-channels feature pre-drilled holes, snap-fit designs, or mounting flanges for fast, secure attachment.

- Budget: Balance cost with performance. Galvanized steel and vinyl are typically most budget-friendly, while custom stainless steel or powder-coated options may carry a premium.

Questions to Ask When Evaluating J Channel Options

- What is the primary use case—siding, trim, wire management, or architectural accent?

- Will the J-channel be exposed to high moisture, chemicals, or UV rays?

- Is a standard size sufficient, or is custom fabrication required?

- Does the supplier offer matching accessories (corner pieces, end caps, connectors)?

- What is the expected installation method—nailing, screwing, snap-fit, or adhesive?

- Are there code or compliance requirements for fire, electrical, or structural performance?

Benefits of Using J-Channels

J-channels offer a range of benefits that make them a staple in modern construction and remodeling:

- Weather Resistance: Seals siding edges and prevents water intrusion, prolonging the life of building materials.

- Enhanced Appearance: Delivers a polished, professional look to any siding or trim installation.

- Versatility: Suitable for numerous materials and project types—including vinyl, steel, wood, and composite panels.

- Ease of Installation: Simple tools and methods mean reduced labor costs and faster project completion.

- Low Maintenance: Most J-channels require minimal upkeep, retaining their appearance and function over time.

- Cost Efficiency: Reduces waste and installation time compared to traditional wood trim or custom flashing.

- Customizable: Available in a wide range of sizes, materials, and finishes to meet any project specification.

Choosing the Correct J-Channel Supplier

Selecting a reliable J-channel supplier is crucial for ensuring product quality, timely delivery, and technical support throughout your project. To achieve the best results when purchasing J-channels, we recommend the following steps:

- Compare at least five suppliers from our comprehensive J-channel directory to evaluate price, quality, and service.

- Review each supplier's business profile to understand their experience, material offerings, and custom fabrication capabilities.

- Use our direct contact forms to request additional information, technical data, or quotes tailored to your specific requirements.

- Access our patented website previewer to quickly assess each supplier’s specialties, certifications, and available stock.

- Take advantage of our streamlined RFQ (Request for Quote) form to reach multiple suppliers with a single inquiry, saving time and ensuring competitive pricing.

Ready to Find the Right J Channel for Your Needs?

Browse our J-channel supplier directory now to compare options, request samples, or get expert advice. Whether you're a contractor, architect, facilities manager, or DIY enthusiast, our resources make it easy to source the ideal J-channel for your next project.

Frequently Asked Questions About J Channels

- What size J-channel do I need for standard vinyl siding?

Most standard vinyl siding installations require a 3/4" or 1" J-channel. Confirm with your siding manufacturer for precise compatibility. - Can J-channels be painted?

Metal J-channels can be powder coated or painted with the appropriate primer and finish. Vinyl J-channels are available in pre-finished colors but can also be painted with specialty vinyl-safe paints. - How do I cut J-channels to size?

Use tin snips for metal J-channels and a fine-toothed saw or utility knife for vinyl or PVC J-channels. Always wear appropriate safety gear. - Are custom J-channel profiles available?

Yes, many suppliers offer custom fabrication for non-standard dimensions, shapes, or finishes. - What is the expected lifespan of a J-channel?

High-quality J-channels, properly installed and maintained, can last 20 years or more. Material choice and environmental exposure are key factors.

Conclusion: Why J-Channels are a Smart Investment

As a critical component in construction and siding, J-channels deliver unmatched flexibility, protection, and aesthetics for a wide range of projects—from residential renovations to large-scale commercial builds. Choosing the right J-channel ensures seamless installation, long-term durability, and a polished finish. By understanding the available materials, manufacturing processes, and supplier options, you can confidently select the ideal J-channel for your unique requirements.

Ready to start your project or need expert guidance? Contact us today for help finding the perfect J-channel solution for your application.

Cold Headed Parts

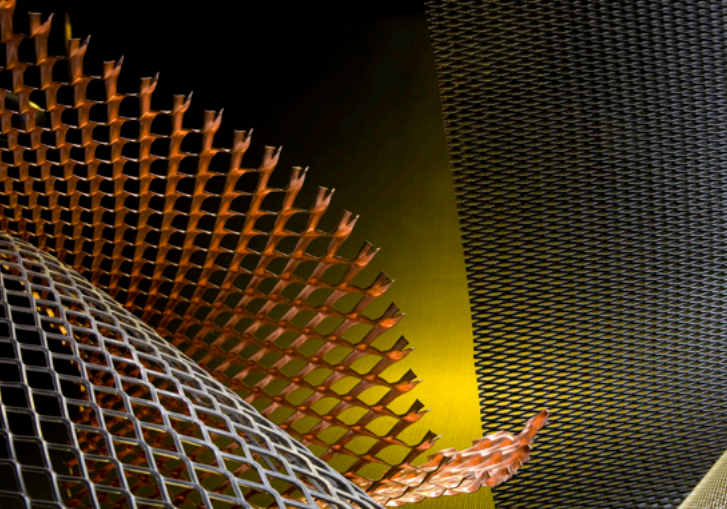

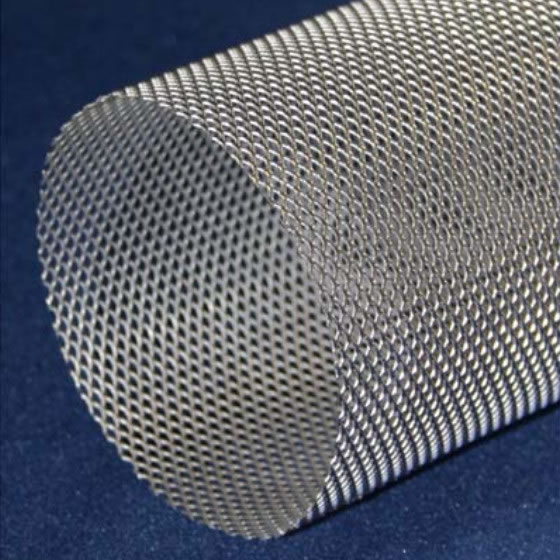

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services