A C-channel is a style of beam with two flanges rising from just one side of the flat surface and a large central part. The C-channel gets its name from the C shape it makes when it is turned on its side. For the greatest contact area and strength, a C-channel is typically utilized in locations where it can be fastened to a flat surface. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

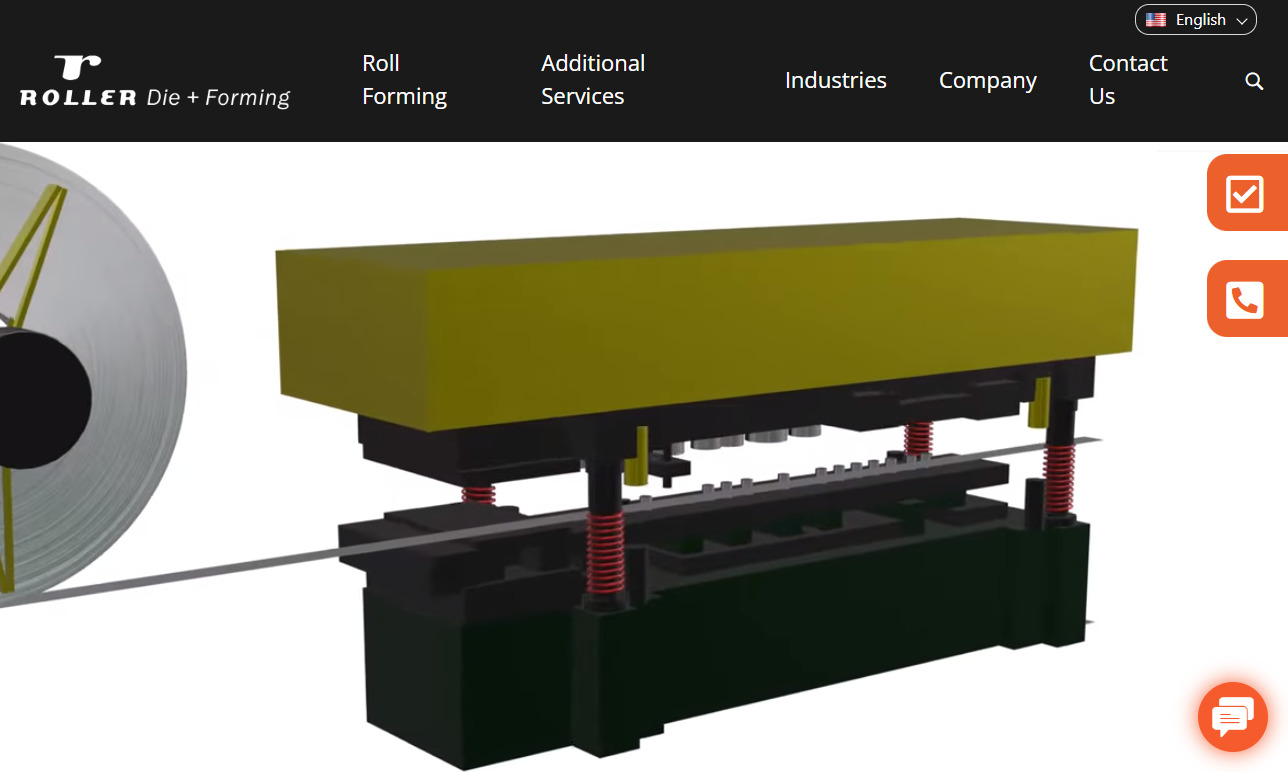

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc. They provide in-house tool room for quality metal moldings and the employees have been trained in every aspect of the roll forming process, representing over 200 years of experience.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture. Our 40,000-square-foot facility enables us to perform a variety of additional processes such as custom packaging, welding, and riveting. For more information on what we can do for you, call or visit our ...

At MMC Roll Form, we specialize in delivering precision-engineered roll formed parts tailored to meet the unique requirements of every project. With over five decades of experience, we’ve built a reputation as trusted partners in the roll forming industry by combining technical expertise with a commitment to personalized service.

More C Channel Companies

What are C Channels?

C channels, also known as channel beams or structural channels, are a type of metal profile characterized by their C-shaped cross-section. Widely used in construction, manufacturing, and engineering, C channels offer a unique combination of strength, versatility, and adaptability. Their design makes them ideal for supporting loads, framing structures, and providing structural reinforcement in a variety of applications. Because of their distinctive shape, C channels are frequently chosen for projects that require both rigidity and flexibility.

One common use for C channels is in the fabrication of I-beams. By welding two C-channels back to back, manufacturers can create an I-beam configuration that provides even greater structural support while maintaining adaptability. This configuration is especially popular in heavy-duty construction, civil engineering, and industrial machinery frameworks.

Are you looking for information on how C channels compare to other structural steel components? Explore the differences between C channels, U channels, and I-beams to make an informed decision for your next project.

How C Channels are Made

A C-channel is a structural steel profile featuring two flanges rising from one side of a flat web, forming its signature C shape when viewed from the end. This design not only maximizes surface contact area when fastened to flat surfaces but also delivers exceptional load-bearing capabilities in various structural and mechanical applications.

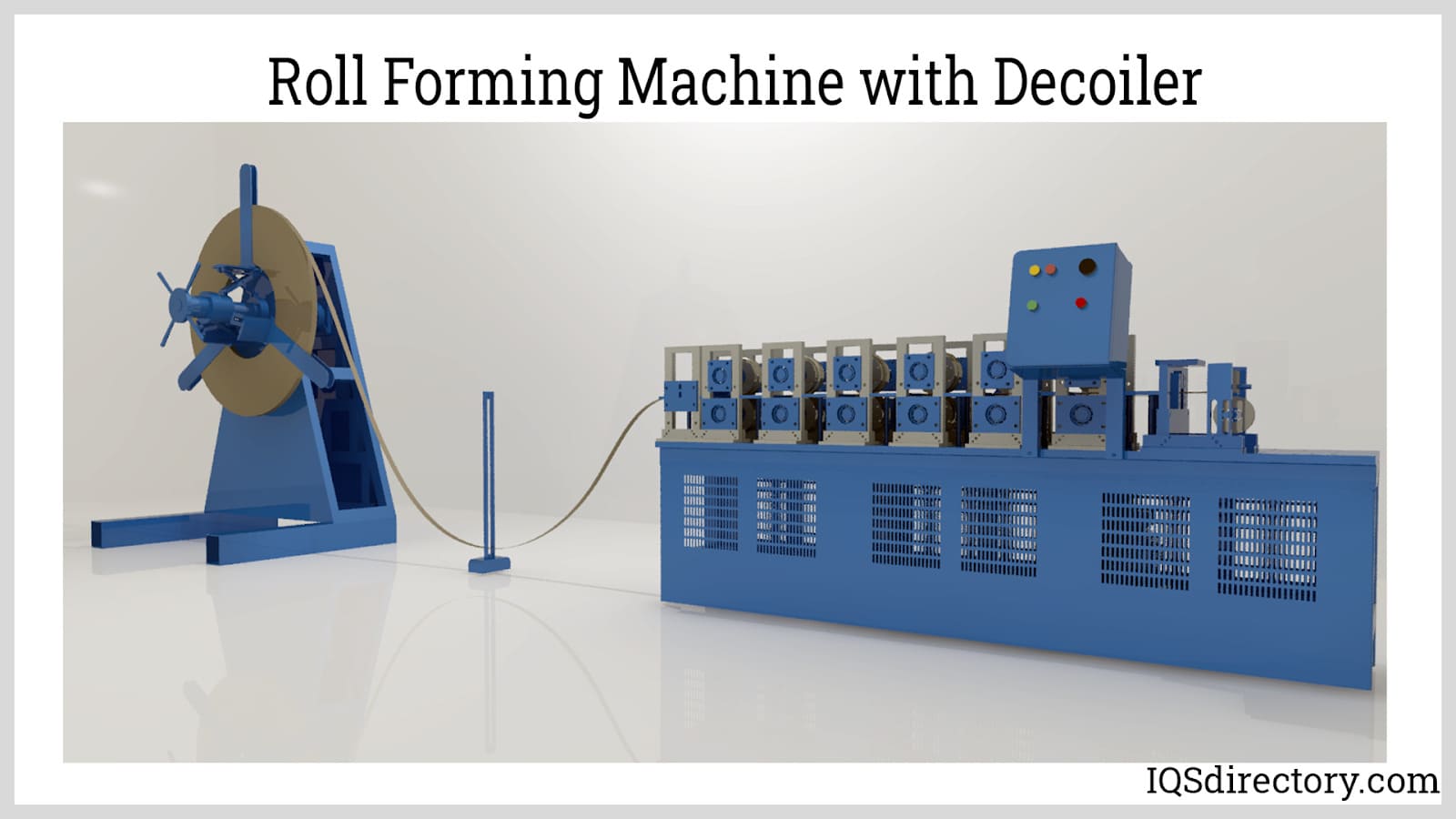

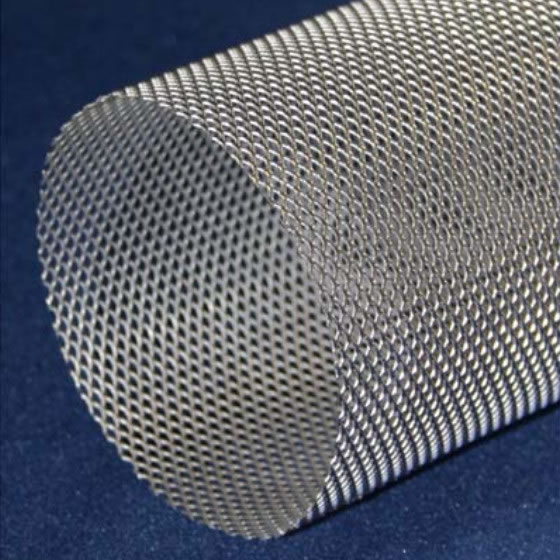

Typically, C channels are manufactured using a roll forming process. This continuous method involves passing a metal strip—such as steel, aluminum, or brass—through a series of precisely engineered dies and rollers. Each station in the roll forming machine incrementally bends the metal, gradually shaping it into a C-channel profile tailored to the desired specifications.

The roll forming process begins with the preparation of the metal strip, which is carefully pre-processed to ensure a square and straight entry into the first set of rollers. After exiting the uncoiler, the strip passes through entry guides to prevent misalignment, promoting consistency and dimensional accuracy. Each die station along the roll forming machine further shapes the metal, with the number of passes required determined by the complexity of the channel design—ranging from a handful for basic profiles to more than thirty for intricate or custom C channels.

Precision is crucial throughout roll forming, as the quality of the finished C channel depends on accurate alignment and gradual, controlled shaping. At the final stage of production, the continuous C-channel is cut to precise lengths, then gathered for inspection and packaging. Depending on end-use requirements, additional processes such as straightening, punching, or finishing may also be applied either at the beginning or end of the roll forming line.

Curious about how roll forming compares to other methods like extrusion or press braking for C channel production? Learn about the advantages of roll forming for high-volume, precision C channel manufacturing and how to select the right process for your application.

Materials Used to Produce C Channels

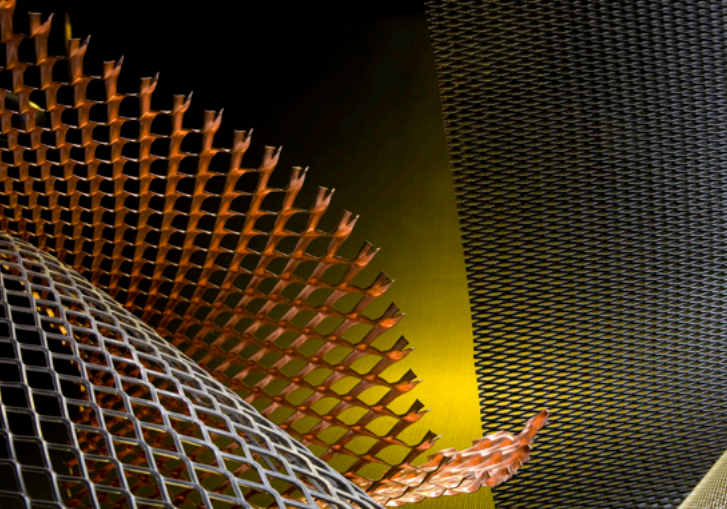

C channels can be fabricated from a variety of metals, each offering unique mechanical properties, performance characteristics, and suitability for specific environments or structural demands. The most common materials include aluminum, steel, and brass, but other alloys or specialty metals may also be used depending on project requirements.

Aluminum

Aluminum C channels are valued for their lightweight nature, corrosion resistance, and versatility. While aluminum does not have the same tensile strength as steel, it provides sufficient stability for many construction, manufacturing, and architectural applications. Its excellent formability and machinability make it ideal for custom channel profiles and precision components.

Typical uses for aluminum channels include frame extensions, light poles, window and door frames, connectors, and the production of lightweight ladders. Additionally, because of aluminum's high thermal and electrical conductivity, aluminum C channels are often used as heat conductors, reflectors, and in electronic enclosures. Looking for a material that is both strong and easy to work with? Discover the benefits of choosing aluminum C channels for your lightweight structural applications.

Steel

Steel C channels are the go-to choice for projects demanding maximum strength, durability, and load-bearing capacity. Available in a range of grades—such as carbon steel, galvanized steel, and stainless steel—these channels are extensively used in building construction, heavy equipment manufacturing, transportation infrastructure, and industrial frameworks.

Steel channels serve as braces, frames, supports, and reinforcements for buildings, bridges, machinery, and more. Their superior resistance to deformation under heavy loads makes them ideal for structural applications where safety and stability are critical. Considering a steel C channel for your next build? Compare different steel grades and finishes to find the optimal balance of strength, corrosion resistance, and longevity.

Brass

Brass C channels are chosen for their aesthetic appeal as well as their mechanical properties. Architectural bronze (Brass 385) is a popular choice thanks to its strength, corrosion resistance, and exceptional workability. This makes brass channels suitable for decorative supports, shelving, wall brackets, and high-end architectural features.

Brass channels can be manufactured to precise tolerances and custom lengths, making them ideal for detailed architectural projects and exhibition displays. Need a channel profile that combines beauty and functionality? Explore brass C channel options for your decorative or architectural applications.

Other Materials

In addition to aluminum, steel, and brass, C channels can also be made from stainless steel, copper, titanium, and other alloys for specialized applications. For example, stainless steel C channels offer excellent corrosion resistance for marine or chemical environments, while copper channels are favored for electrical grounding systems. When selecting a material, consider the application environment, load requirements, and desired lifespan of your structure.

Applications of C Channels

C channels are among the most versatile structural components available, finding use in countless sectors, including construction, infrastructure, manufacturing, transportation, and renewable energy. Their unique shape and strength-to-weight ratio make them suitable for a wide array of load-bearing and support roles. Some of the most common applications include:

- Roof Deck Supports and Rafters: C channels are frequently employed as rafters and roof deck supports, extending from the eaves to the ridge. Steel or aluminum channels can match or exceed the weight-bearing capacity of traditional materials while remaining lighter and more compact. Their inherent resistance to rot, corrosion, and moisture makes them a superior alternative to wood in many roofing systems. Looking to extend the lifespan of your roof deck? See how C channels outperform wood and reduce maintenance costs.

- Solar Panel Mounting Systems: The renewable energy industry relies on C channels for mounting solar panels on rooftops and ground arrays. Their high tensile strength and light weight enable solar panels to withstand wind, snow, and other harsh weather conditions, while simplifying installation and minimizing structural loads. Need a reliable solution for solar panel support? Compare steel and aluminum C channels for your next solar project.

- Building Frames and Structural Supports: C channels serve as essential framing components in commercial, industrial, and residential construction. They are used for wall studs, floor joists, bracing, and support beams, offering flexibility in design and rapid installation. Explore how C channels can streamline your building process and enhance structural integrity.

- Machinery and Equipment Frames: In manufacturing and industrial settings, C channels form the backbone of machinery frames, conveyor supports, and automation systems. Their adaptability allows for easy integration with other structural shapes, helping engineers design efficient and robust equipment layouts. Curious about customizing C channel profiles for your machinery? Find out how custom fabrication options can meet your exact requirements.

- Transportation Infrastructure: C channels are used in bridges, railways, trailers, and truck frames due to their durability and resistance to vibration and impact. Their standardized dimensions and compatibility with other steel shapes simplify the design and assembly of transportation systems. Learn how C channels contribute to safer, longer-lasting infrastructure.

Looking for industry-specific C channel solutions? Contact our team to discuss custom C channel profiles for your unique application.

Benefits of Using C Channels

Choosing C channels for your structural or architectural project offers a range of advantages that can improve performance, reduce costs, and extend the lifespan of your build. Key benefits include:

- High Strength-to-Weight Ratio: C channels provide significant load-bearing capacity without excessive weight, making them ideal for applications where weight savings are essential, such as aerospace, automotive, and renewable energy projects.

- Corrosion Resistance: When produced from materials like galvanized steel, aluminum, or stainless steel, C channels offer excellent resistance to rust and environmental degradation, minimizing maintenance and repair needs.

- Design Flexibility: C channels are available in a wide range of sizes, thicknesses, and materials, allowing engineers and architects to select the perfect profile for any application.

- Ease of Fabrication and Installation: Their uniform cross-section and compatibility with standard fasteners and connectors make C channels easy to cut, shape, weld, and assemble, reducing labor time and project costs.

- Cost-Effectiveness: Compared to other structural shapes, C channels often deliver superior performance at a lower material and installation cost, making them a budget-friendly option for large- and small-scale projects alike.

- Availability and Standardization: C channels are widely available from multiple suppliers, with standardized dimensions that ensure compatibility and simplify sourcing.

Unsure if C channels are the right choice for your project? Request a consultation with our structural engineering team to review your specifications and recommend the best solution.

Common Questions When Selecting C Channels

Purchasing the right C channel starts with understanding your project’s requirements. Here are some of the most frequently asked questions buyers consider:

- What size C channel do I need? The required dimensions (height, width, thickness) depend on your load-bearing, span, and installation requirements. Use our sizing calculator or speak to an engineer for tailored recommendations.

- Which material is best for my environment? Consider factors such as exposure to moisture, chemicals, temperature fluctuations, and mechanical stress. Galvanized steel and stainless steel are excellent for outdoor or corrosive applications, while aluminum is preferred for lightweight structures.

- How do I ensure proper installation? Follow manufacturer guidelines for cutting, fastening, and supporting C channels. Use compatible fasteners and maintain correct spacing to prevent deflection or failure.

- Can I order custom C channel profiles? Yes, many suppliers offer custom roll forming, punching, and finishing services to meet unique project requirements. Request a quote for custom C channel fabrication.

Ready to compare C channel suppliers? Check our directory for trusted manufacturers and request quotes for your next project.

Choosing the Right C Channel Supplier

Selecting a reliable C channel supplier is crucial for ensuring quality, timely delivery, and competitive pricing. Here’s how to make the best choice:

- Compare Multiple Suppliers: Use our comprehensive C channel directory to evaluate at least four different suppliers. Each listing includes a business profile highlighting areas of expertise, certifications, and manufacturing capabilities.

- Review Product Portfolios: Visit each supplier’s website using our proprietary previewer to see their range of C channel products, materials, finishes, and customization options.

- Check Industry Experience: Choose suppliers with proven experience in your industry—whether it’s construction, solar energy, transportation, or manufacturing—for advice on compliance and best practices.

- Request Detailed Quotes: Use our streamlined RFQ (Request For Quote) form to contact multiple suppliers simultaneously with your project specifications, ensuring you receive accurate pricing and lead times.

- Evaluate Customer Reviews: Read testimonials and case studies to gauge supplier reliability, product quality, and customer service.

To make sure you have the most productive outcome when purchasing C-channels from a C-channel supplier, it is important to compare at least 4 suppliers using our C-channel directory. Each c-channel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each C-channel business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple C-channel businesses with the same message.

Need help finding the right supplier or want guidance on technical specifications? Contact our sourcing specialists for expert advice and supplier recommendations.

Next Steps: Sourcing and Purchasing C Channels

Ready to begin your search for C channels? Start by assessing your project’s load requirements, installation environment, and material preferences. Use our online resources to:

- Browse standardized C channel sizes and profiles by material type (aluminum, steel, stainless steel, brass, copper, and more).

- Access technical datasheets, CAD drawings, and load tables to ensure compatibility with your structural design.

- Compare suppliers by region, industry specialization, and manufacturing capabilities.

- Request samples or prototypes for testing before committing to a bulk order.

- Get quotes and lead times for standard and custom C channel orders.

Whether you are seeking C channels for construction, industrial machinery, solar panel mounting, or architectural projects, our platform provides all the tools and information you need to make an informed decision and streamline your procurement process.

Start your C channel search today—browse our directory or contact us for personalized assistance!

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services